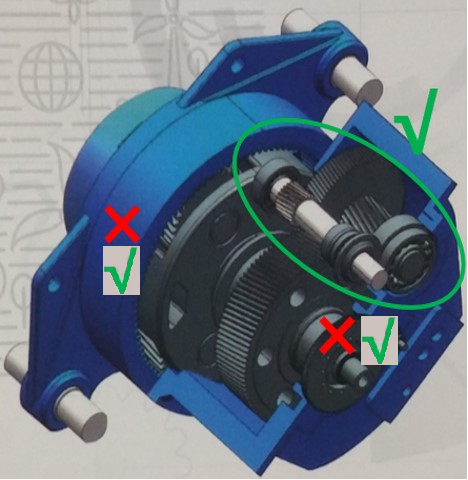

This product is suitable for asynchronous double-fed wind turbine, using customized design tools, realizing the replacement of low speed shaft and row star parts of gearbox on tower. Traditional maintenance schemescan only replace the high speed shaft and the medium

speed shaft on tower. This product can significantly reduce the removal of gearboxes and return to the factory for maintenance, which is great significant for the cost saving and efficiency improvement of old wind farms.

No large ground crane, small footprint, Less afforestationdamage, This special tools is suitable for various wind turbine types, which is with modular design, convenient transportation, can save 50% gearbox replacement cost, especially suitable for large crane approach difficult areas, high towers and offshore wind farms. It has obtained the certificate of technical evaluation and tower maintenance capability evaluation issued by CGC.

Products

▶ Multibrand Spare Parts and Service

Tools Container

Gearbox Repair On Tower

▶ Low Speed Shaft Replacement on Tower